Why Metal Roofing Installation is the Smart Choice for Property Owners

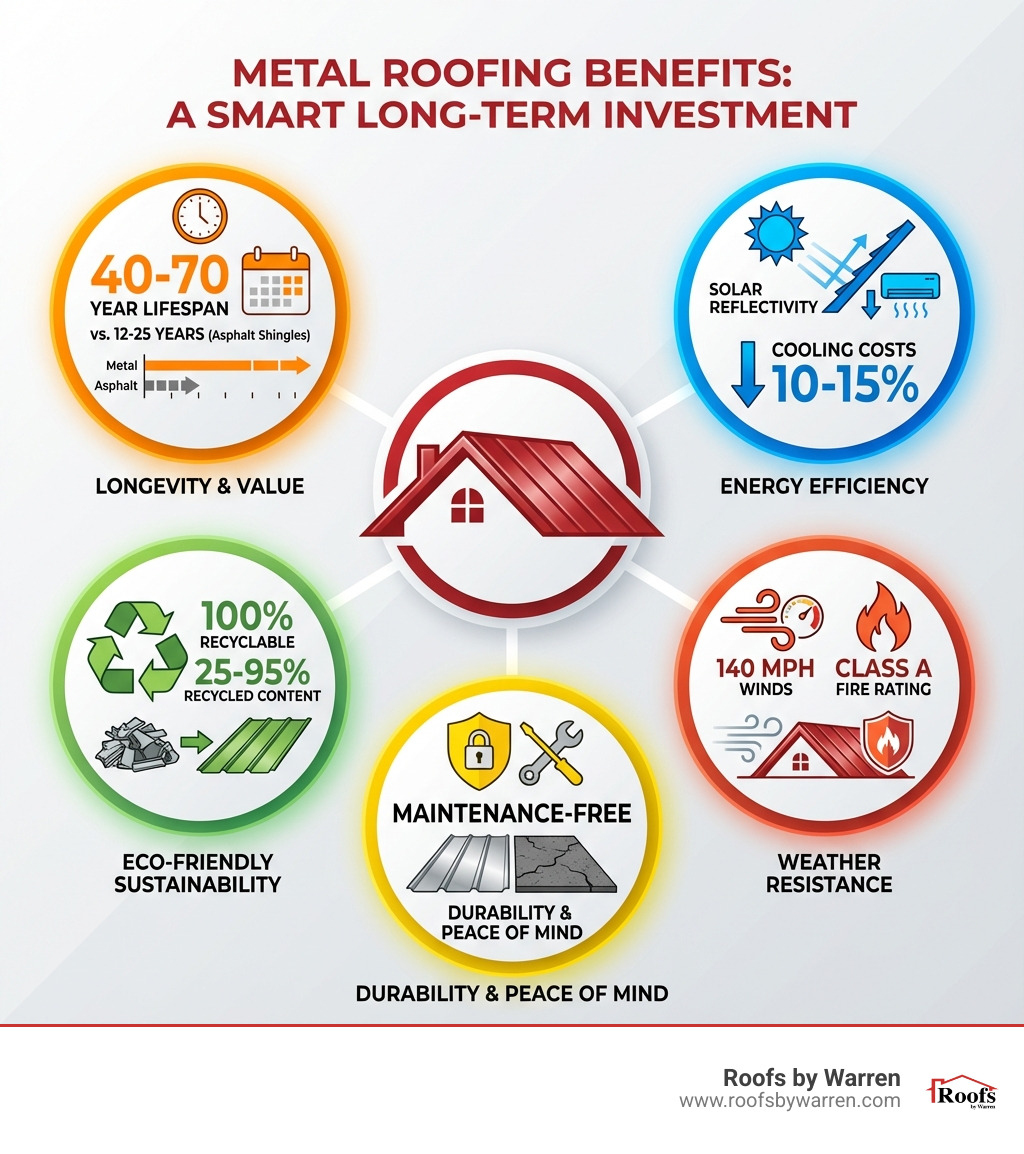

Metal roofing installation is a critical investment that transforms your property with a durable, energy-efficient, and attractive roofing solution that can last 40 to 70 years or more. Unlike traditional asphalt shingles that need replacement every 12 to 25 years, a properly installed metal roof provides exceptional protection and value for decades.

Quick Answer: What is Metal Roofing Installation?

Metal roofing installation involves these essential steps:

- Preparing the roof deck – Inspecting and repairing the underlying structure

- Installing underlayment – Adding a protective barrier beneath the panels

- Setting trim and flashing – Installing eave, gable, and valley components

- Placing and fastening panels – Aligning metal panels and securing them properly

- Sealing seams and overlaps – Ensuring watertight connections

- Installing ridge caps – Completing the peak with ventilated closures

Professional installation typically takes 2-5 days depending on roof size and complexity.

When it comes to protecting your home or business, metal roofing has evolved from a purely industrial material to a premium roofing choice for property owners who value longevity and performance. Modern metal roofs combine sleek aesthetics with best durability, standing up to high winds up to 140 miles per hour, heavy snow loads, hail, and even fire.

The key to maximizing these benefits lies in proper installation. While metal roofing materials are inherently durable, expert craftsmanship during installation determines whether your roof will perform flawlessly for decades or face premature issues. From selecting the right materials and profiles to ensuring precise fastening and sealing techniques, every step matters.

This comprehensive guide walks you through everything you need to know about metal roofing installation, from choosing materials and understanding the installation process to finding a qualified contractor who will deliver lasting results.

Why a Metal Roof is a Superior Long-Term Investment

Choosing a metal roof for your property in Urbana, London, Grove City, Pickerington, Bellefontaine, or anywhere in Central Ohio is choosing a future of peace of mind. Our metal roofing systems offer unparalleled longevity, durability, and protection against the elements, making them a truly superior long-term investment.

Metal roofs are renowned for their exceptional lifespan, typically lasting 40 to 70 years, and often even longer with proper maintenance. This is a significant advantage over traditional asphalt shingles, which usually require replacement every 12 to 25 years. This extended lifespan means fewer replacements over the life of your home or business, translating into long-term savings and less hassle.

Durability and Weather Performance

The inherent strength of metal makes it incredibly durable against various weather conditions common in Ohio.

- High Winds: Metal roofs are engineered to withstand extreme wind speeds, often up to 140 miles per hour, far surpassing the resistance of many conventional roofing materials. This robust performance helps protect your property during severe storms.

- Heavy Snow: The smooth, hard surface of a metal roof allows snow to shed more easily than on other roofing types, reducing the risk of heavy snow accumulation and potential structural stress. This characteristic also helps prevent the formation of ice dams, a common issue in colder climates.

- Hail Resistance: Many metal roofing systems are highly resistant to hail damage, often earning a Class 4 impact resistance rating. This means they can endure significant hail without denting or puncturing, a crucial benefit for protecting your investment.

- Fire Safety: With a Class A fire rating, metal roofs are non-combustible, providing superior protection against external fire sources. This can be a critical safety feature and may even lead to lower insurance premiums for your property.

For more insights into how metal roofing stands up to challenging weather, explore How metal roofing protects London, Ohio homes from harsh winter weather.

Energy Efficiency and Sustainability

Beyond durability, metal roofs offer significant benefits for energy efficiency and environmental sustainability.

- Solar Reflectivity: Many metal roofs feature cool roof pigments and highly reflective surfaces that reflect solar radiant heat away from your building. This significantly reduces heat gain, especially during hot Ohio summers.

- Reduced Cooling Costs: By minimizing heat absorption, metal roofs can lower your cooling costs by 10-15%, making your home or business more comfortable and energy-efficient.

- Recycled Content and Recyclability: Metal roofing materials often contain a high percentage of recycled content (ranging from 25-95%), and they are 100% recyclable at the end of their long life. This drastically reduces landfill waste compared to asphalt shingles, which contribute billions of pounds of waste annually. Choosing a metal roof is an environmentally responsible decision that supports a healthier planet.

To understand the financial advantages of these features, read about How homeowners in Grove City, OH can receive long-term savings after a metal roof installation.

Choosing the Right Materials and Style for Your Home

When considering a metal roofing installation, the choices in materials and styles are vast, allowing us to match both the aesthetics and functionality you desire for your home or business. We believe your roof should not only protect but also improve your property’s curb appeal and align with its architectural style.

An Overview of Metal Roofing Materials

The metal roofing industry offers several high-quality materials, each with unique advantages. We’ll help you select the best fit for your specific needs and preferences.

| Material | Pros | Cons | Best For |

|---|---|---|---|

| Steel (Galvanized or Galvalume) | Strong, durable, fire-resistant, wide range of colors/finishes, high recycled content, good value. G90 galvanized for corrosion resistance, Galvalume (AZ50, AZ55) for improved protection. | Can corrode if coatings are compromised, heavier than aluminum, potential for oil canning with wide panels. | General residential and commercial use, standing seam, corrugated, or metal tile profiles. Excellent all-rounder for Ohio weather. |

| Aluminum | Lightweight, excellent corrosion resistance (especially useful near coastal areas, though less critical in Ohio), good for custom shapes. | Softer, more prone to denting than steel, can be more expensive than steel. | Areas where weight is a concern, or for highly custom architectural designs. |

| Copper | Extremely long lifespan (200+ years), develops a beautiful, distinctive patina, very durable, maintenance-free. | Very expensive, limited color options (natural patination is the appeal), can be loud during rain if not properly installed. | High-end custom homes, historic properties, or architectural accents where aesthetics and ultimate longevity are paramount. |

| Zinc | Very long lifespan, self-healing patina that protects against corrosion, unique aesthetic, excellent malleability. | High upfront cost, limited color choices, can be susceptible to “oil canning” (visible waviness) if not installed carefully. | Premium architectural projects, contemporary designs, or where exceptional longevity and a distinct natural finish are desired. |

When selecting your metal, consider its gauge (thickness). While 26 gauge is widely accepted for residential use, a 24 gauge is often recommended for areas prone to severe weather, including hail or high winds, providing improved durability.

Exploring Metal Roofing Profiles

Beyond the material, the profile of your metal roof dramatically influences its appearance and performance.

- Standing Seam: This is a popular and sleek choice, characterized by raised, interlocking seams that run vertically up the roof. The fasteners are concealed beneath the panels, creating a clean, modern aesthetic and enhancing watertightness. Standing seam roofs are highly durable and perform exceptionally well in shedding water and snow.

- Corrugated Panels: Often associated with a more traditional or rustic look, corrugated panels feature a wavy or ribbed pattern. These panels are typically installed with exposed fasteners, making them an economical and straightforward option. Modern corrugated panels come in various colors and finishes, allowing for a contemporary twist on a classic style.

- Metal Shingles or Tiles: For those who love the classic look of asphalt shingles, slate, or wood shakes but desire the benefits of metal, metal shingles and tiles are an excellent choice. These panels are stamped or formed to mimic traditional roofing materials, offering a wide range of aesthetic options while providing the superior durability and longevity of metal.

The choice of profile depends on your desired aesthetic, the architectural style of your home or business, and your budget. Our team can guide you through the options, ensuring the chosen profile meets both your functional and aesthetic requirements.

The Professional Metal Roofing Installation Process

A successful metal roofing installation is a blend of high-quality materials and expert craftsmanship. Even the best metal roof won’t perform optimally without a precise and professional installation. We adhere strictly to manufacturer specifications and industry best practices to ensure your roof provides decades of reliable protection. The National Roofing Contractors Association (NRCA) emphasizes the importance of following detailed installation guidelines, which we incorporate into every project. For comprehensive technical guidance, you can refer to resources like the Metal Roof Installation Manual – National Roofing Contractors Association.

Pre-Installation: Preparing for a Successful Project

The foundation of a flawless metal roof begins long before the first panel is laid.

- Roof Inspection and Deck Assessment: Our process starts with a thorough inspection of your existing roof and underlying deck. We look for any signs of damage, rot, or structural issues. If your current roof is nearing the end of its life, we assess the condition of the plywood or other decking material.

- Plywood Repair and Remediation: Should we find any damaged plywood, perhaps caused by mold or water intrusion, we ensure it is fully repaired or replaced. Mold remediation is performed if necessary, ensuring a clean and sound surface for your new roof. A customer recently praised a company for removing damaged plywood and performing mold remediation before installing metal sheets, highlighting the importance of this step.

- Old Roof Removal (Full Tear-Off): While it is sometimes possible to install a metal roof over existing shingles, our best practice recommendation for a long-lasting, problem-free metal roof is a full tear-off. This allows us to inspect the entire roof deck, make any necessary repairs, and ensure a perfectly smooth and stable surface for the new metal panels. This approach prevents issues like trapped moisture, unevenness, or exceeding weight limits. For more on this transition, see Transition from shingle to metal roof.

- Underlayment Installation: Once the deck is pristine, we install a high-quality underlayment. This protective barrier, often a synthetic, self-adhering ice and water shield, is crucial for waterproofing. It acts as a secondary defense against moisture, providing an extra layer of protection beneath the metal panels. For shallow-pitched roofs, a self-healing ice-and-water membrane is particularly important. Underlayment layers are typically overlapped by six to eight inches to ensure continuous coverage.

A Step-by-Step Guide to a Flawless Metal Roofing Installation

Our experienced team follows a meticulous process to ensure your metal roofing installation is completed to the highest standards.

- Tools and Materials: We come equipped with all the essential tools for a precise installation, including aviation snips for cutting metal, specialized drills for fasteners, hand seamers for bending trim, and caulk guns for applying sealants. We use high-quality metal panels, closure strips, butyl tape, and appropriate fasteners.

- Strapping Installation (if needed): In some cases, particularly for certain panel types or roof structures, 1″ x 4″ strapping may be installed over the underlayment. This creates an air gap for ventilation and provides a solid base for fastening panels.

- Eave and Gable Trim Installation: We begin by installing eave trim along the bottom edge of the roof and gable trim along the rake edges. These trims provide a finished look, protect the edges of the roof deck, and direct water runoff. Trims are carefully cut, bent, and spliced with sealant to ensure a seamless, watertight connection. For climates prone to ice dams, eave trim is installed atop the underlayment.

- Panel Alignment and Starting Square: To ensure a perfectly straight and aesthetically pleasing roof, we use precise methods like the 3-4-5 rule (or multiples thereof) to snap a square reference line. This ensures that the first panel is laid perfectly square to the roof, guiding the placement of all subsequent panels.

- Setting and Fastening Panels: Metal panels are carefully positioned, often over inside foam closure strips secured with butyl tape and sealant. Panels typically overhang the eave by about one inch. We use specialized self-drilling screws, chosen for the specific framing material (steel or wood), and fasten them correctly. This means driving screws to seat flat on the roof, avoiding over- or under-tightening, and placing them strategically (e.g., on both sides of every rib at the eave, then spaced no more than 24 inches apart in subsequent rows). Removing metal shavings immediately prevents corrosion.

- Overlapping Panels: For panels designed to overlap, we carefully nest the last rib of each panel together, ensuring a secure and watertight seam. For systems that use mechanical seams, specialized tools are used to bend and interlock the edges.

- Ridge Cap Installation: The final step involves installing the ridge cap along the peak of the roof. This is done with outside closure strips, butyl tape, and sealant, followed by fastening the cap through every rib with appropriate screws. This completes the roof’s weatherproofing envelope and provides a finished look.

For a visual guide and more details on our process, visit How to install metal roofing.

Finding a Trusted Contractor for Your Metal Roofing Installation

Choosing the right contractor for your metal roofing installation is as important as selecting the right materials. We understand that this is a significant investment, and you deserve a team you can trust. Here’s what we offer and what you should look for:

- Workmanship Warranties: We stand behind our work with comprehensive workmanship warranties, often providing a 25-year leak-free guarantee on our installations. This gives you peace of mind knowing that your investment is protected.

- Material Warranties: We use high-quality metal roofing materials that come with robust manufacturer warranties, typically ranging from 40 to 55 years, ensuring the longevity of the product itself.

- Insurance: We are fully licensed and insured, protecting both our team and your property throughout the installation process. Always verify a contractor’s insurance before work begins.

- Local Reputation: Our commitment to integrity and skilled craftsmanship has earned us a strong reputation in Urbana, London, Grove City, Pickerington, Bellefontaine, and across Central Ohio. We encourage you to review our testimonials and see what our satisfied customers say about our attention to detail and customer service. For instance, customers have noted excellent service for custom flashing pieces made quickly and at a reasonable price, and thorough installations including necessary deck repairs.

- Portfolio Review: We are proud to share our portfolio of completed metal roofing projects, showcasing our expertise across various styles and property types. This allows you to see the quality of our work firsthand.

For tips on maintaining your roof after installation, especially during seasonal changes, check out Preparing your metal roof for leaf season in Grove City, OH.

Frequently Asked Questions about Metal Roofs

We often encounter common questions about metal roofing, and we’re here to provide clear answers.

Can a metal roof be installed over existing shingles?

Yes, in many cases, a metal roof can be installed over existing asphalt shingles. This can sometimes save on labor and disposal costs associated with a full tear-off. However, there are important considerations:

- Building Codes: Local building codes in Ohio may have specific requirements or restrictions regarding overlaying roofs. We always verify compliance.

- Manufacturer Recommendations: Metal roofing manufacturers often have guidelines for overlay installations. Adhering to these is crucial for warranty validity.

- Potential Issues: Installing over shingles can add significant weight to your roof structure, create an uneven surface (which can lead to oil canning or aesthetic issues), and potentially trap moisture between the layers if not properly ventilated.

- Best Practice: Full Tear-Off: While overlaying is an option, our best practice recommendation for optimal performance and longevity is a full tear-off. This allows us to thoroughly inspect and repair the roof deck, ensure proper underlayment installation, and create the ideal, flat surface for your new metal roof. This approach ensures maximum lifespan and minimizes future problems.

Are metal roofs noisy during rain?

This is a common misconception, but modern metal roofs are generally not noisy during rain. The “noisy metal roof” stereotype often comes from older installations on agricultural buildings or sheds where the metal was directly exposed to the interior with no underlying structure or insulation.

With a professionally installed residential or commercial metal roof, several factors mitigate noise:

- Solid Decking: Most residential metal roofs are installed over a solid roof deck (plywood or OSB), which provides a significant sound barrier.

- Underlayment and Insulation: The underlayment and any attic insulation further dampen sound, making the pitter-patter of rain on a metal roof often no louder than on an asphalt shingle roof.

- Proper Installation Techniques: Modern installation methods, including the use of sound-deadening strips and careful fastening, also contribute to a quieter roof.

So, rest assured, a properly installed metal roof will not turn your home into a drum during a rainstorm.

How does metal roofing compare to asphalt shingles?

When comparing metal roofing to asphalt shingles, metal consistently comes out ahead in several key areas, making it a superior long-term investment for property owners in Ohio.

| Feature | Metal Roofing metal Metal roofs can last up to 50 years, compared to asphalt shingles (12-25 years).

- Metal roofs can withstand wind speeds up to 140 miles per hour.

- 20 billion pounds of asphalt shingles are disposed of in landfills annually.

- Metal roofs can last up to 100 years with proper maintenance.

- Average lifespan of a metal roof is 40 to 70 years.

- Asphalt shingles or wood shingles typically last between 15 and 30 years.

For a deeper dive into the comparison, we invite you to read Comparing asphalt shingles vs metal roofing and Metal roofing vs asphalt shingles.

Conclusion: Secure Your Home with a Lifetime Roof

Investing in a metal roofing installation for your property in Urbana, London, Grove City, Pickerington, Bellefontaine, or Central Ohio is a decision that pays dividends for decades. We’ve seen how metal roofs offer best longevity, providing 40 to 70 years or more of reliable service, far surpassing traditional materials. They deliver superior protection against extreme weather, including high winds, heavy snow, and hail, while offering excellent fire resistance. Beyond durability, metal roofs contribute to energy efficiency by reflecting solar heat, potentially lowering your cooling costs, and their high recycled content and recyclability make them an environmentally responsible choice.

The key to open uping these benefits lies in expert craftsmanship during installation. Our commitment to integrity, skilled artistry, and comprehensive service ensures that every metal roofing installation we undertake is completed to the highest standards, promising a lifetime of protection and improved property value.

When you choose us for your metal roofing needs, you’re not just getting a new roof; you’re securing a long-term, low-maintenance solution that will protect your home or business for generations.